Fluid Mechanics PYQ Set (2000 to 2025)

(A) \( \dfrac{\tau_w}{2} \)

(B) 2\(\tau_w\)

(C) 1\(\tau_w\)

(D) \( \dfrac{\tau_w}{\sqrt{2}} \)

Solution =

To determine the wall shear stress at a location 30 mm from the leading edge, we analyze the flow over a flat plate and how the wall shear stress varies with distance from the leading edge.

⦾ Given:

✓ Density of air (\(\rho\)): \(1.2\ \text{kg/m}^3\)

✓ Kinematic viscosity (\(\nu\)): \(1.5 \times 10^{-5}\ \text{m}^2/\text{s}\)

✓ Free-stream velocity (\(U\)): \(2\ \text{m/s}\)

✓ Wall shear stress at 15 mm (\(\tau_{w1}\)): \(\tau_w\)

✓ Distance 1 (\(x_1\)): \(15\ \text{mm} = 0.015\ \text{m}\)

✓ Distance 2 (\(x_2\)): \(30\ \text{mm} = 0.030\ \text{m}\)

⦾ Key Concepts:

For laminar flow over a flat plate, the wall shear stress (\(\tau_w\)) is given by:

\[ \tau_w = 0.332 \rho U^2 \left( \frac{U x}{\nu} \right)^{-1/2} \] This shows that the wall shear stress is inversely proportional to the square root of the distance from the leading edge:

\[ \tau_w \propto \frac{1}{\sqrt{x}} \] ⦾ Calculation:

Let \(\tau_{w2}\) be the wall shear stress at \(x_2 = 30\ \text{mm}\).

Using the proportional relationship:

\[ \frac{\tau_{w2}}{\tau_{w1}} = \sqrt{\frac{x_1}{x_2}} = \sqrt{\frac{0.015}{0.030}} = \sqrt{\frac{1}{2}} = \frac{1}{\sqrt{2}} \] ⦾ Thus:

\[ \tau_{w2} = \frac{\tau_{w1}}{\sqrt{2}} = \frac{\tau_w}{\sqrt{2}} \] Final Answer: \[ \boxed{\dfrac{\tau_w}{\sqrt{2}}} \]

(A) For the same maximum velocity, the average velocity is higher in the turbulent regime than that of the laminar regime

(B) Compressibility effects are important if Mach number is less than 0.3

(C) For laminar flow, the friction factor is independent of surface roughness

(D) For laminar flow, friction factor decreases with decrease in Reynolds number

Solution =

⦾ Option A) “For the same maximum velocity, the average velocity is higher in the turbulent regime than that of the laminar regime.”

✓ Correct= In laminar flow, the velocity profile is parabolic:

\[ V_{avg} = \frac{1}{2}V_{max} \] In turbulent flow, the velocity profile is flatter (due to mixing):

\[ V_{avg} \approx 0.8V_{max} \text{ to } 0.9V_{max} \] Conclusion: For the same \(V_{max}\), \(V_{avg}\) is indeed higher in turbulent flow.

⦾ Option B) “Compressibility effects are important if Mach number is less than 0.3.”

✗ Incorrect = Compressibility effects become significant when:

\[ Ma > 0.3 \] For \(Ma < 0.3\), flow is typically treated as incompressible.

Conclusion: The statement reverses the correct condition.

⦾ Option C) “For laminar flow, the friction factor is independent of surface roughness.”

✓ Correct = Laminar flow friction factor depends only on Reynolds number:

\[ f = \frac{64}{Re} \] Surface roughness affects only turbulent flow friction factors.

Conclusion: The statement is correct.

⦾ Option D) “For laminar flow, friction factor decreases with decrease in Reynolds number.”

✗ Incorrect = The laminar friction factor relationship:

\[ f = \frac{64}{Re} \] This shows that \(f\) increases as \(Re\) decreases.

Conclusion: The statement is exactly opposite of the truth.

⦾ Final Answer = The correct options are: \[ \boxed{A \text{ and } C} \]

(A) Nikuradse stresses

(B) Reynolds stresses

(C) Boussinesq stresses

(D) Prandtl stresses

Solution =

Reynolds stresses arise from the time-averaged product of fluctuating velocity components in turbulent flow:

\[ \tau_{ij}^{\text{Reynolds}} = -\rho \overline{u_i’ u_j’} \]

These are responsible for the additional momentum transport in turbulent flows and are modeled using the concept of eddy viscosity.

Boussinesq introduced a hypothesis to relate Reynolds stresses to the mean rate of strain using eddy viscosity:

\[ \tau_{ij}^{\text{Reynolds}} \approx \mu_t \left( \frac{\partial \overline{u_i}}{\partial x_j} + \frac{\partial \overline{u_j}}{\partial x_i} \right) \]

But the physical origin is still the Reynolds stresses.

⦾ Correct Answer: B. Reynolds stresses

(A) positive, but more than one atmosphere

(B) negative

(C) zero

(D) positive, but less than one atmosphere

Solution =

⦾ Explanation:

✓ A barometer measures atmospheric pressure using a column of mercury in a closed-end glass tube.

✓ The space above the mercury column is essentially a vacuum or near-vacuum (called the Torricellian vacuum).

In this space: There is very little mercury vapour.

The pressure is extremely low compared to atmospheric pressure.

⦾ Key Concept:

Gauge pressure is defined as:

Gauge Pressure = Absolute Pressure – Atmospheric Pressure

Since the absolute pressure in the vacuum space is near zero:

\[ \text{Gauge Pressure} = 0 – 1\, \text{atm} = -1\, \text{atm} \]

So, the gauge pressure is negative.

Final Answer: Option B — Negative

(A) Centre of buoyancy must be above the centre of gravity

(B) Centre of buoyancy must be below the centre of gravity

(C) Metacentre must be at a higher level than the centre of gravity

(D) Metacentre must be at a lower level than the centre of gravity

Solution =

⦾ Explanation:

✓ Centre of Gravity (G): Point at which the weight of the body acts.

✓ Centre of Buoyancy (B): Centroid of the submerged volume (point of buoyant force).

✓ Metacentre (M): Point where the line of action of buoyant force intersects the vertical axis when tilted.

For a floating body to be in stable equilibrium:

Metacentre (M) must be above Centre of Gravity (G)

So,

\[ MG > 0 \]

This ensures that a restoring moment is produced when the body is tilted.

⦾ Summary Table: (Condition => Stability)

✓ \( M > G \) => Stable

✓ \( M = G \) => Neutral

✓ \( M < G \) => Unstable

⦾ Final Answer: Option C — Metacentre must be at a higher level than the centre of gravity

(A) 0.1

(B) 0.3

(C) 2.5

(D) 2.93

Solution =

⦾ Given:

✓ Initial pressure: \( P_1 = 1 \, \text{bar} = 10^5 \, \text{Pa} \)

✓ Final pressure: \( P_2 = 30 \, \text{bar} = 30 \times 10^5 \, \text{Pa} \)

✓ Density: \( \rho = 990 \, \text{kg/m}^3 \)

✓ We are to calculate the isentropic specific work done by the pump:

\[ w = \frac{P_2 – P_1}{\rho} \]

⦾ Step-by-step:

\[ \Delta P = P_2 – P_1 = (30 – 1) \times 10^5 \]\[= 29 \times 10^5 \, \text{Pa} \]

\[ w = \frac{29 \times 10^5}{990} = \frac{2900000}{990} \]\[\approx 2929.29 \, \text{J/kg} = 2.93 \, \text{kJ/kg} \]

⦾ Final Answer: D) 2.93

(A) Metacentre should be below centre of gravity

(B) Metacentre should be above centre of gravity

(C) Metacentre and centre of gravity must lie on the same horizontal line

(D) Metacentre and centre of gravity must lie on the same vertical line

Solution =

⦾ Explanation:

For a floating body to be stable under gravity, the metacentre (M) must lie above the centre of gravity (G). This ensures that when the body tilts, the buoyant force and gravity create a restoring moment that returns the body to equilibrium.

⦾ Key Definitions:

✓ Metacentre (M): The intersection point of the buoyant force line (after tilting) and the original vertical axis.

✓ Centre of Gravity (G): The point where the entire weight of the body acts.

Stability Conditions:

Stable Equilibrium: \( M \) above \( G \)

→ Generates a restoring moment: \( \tau = W \cdot GM \cdot \sin\theta \)

where \( W \) is weight, \( GM \) is metacentric height, and \( \theta \) is tilt angle.

Unstable Equilibrium: \( M \) below \( G \)

→ Generates an overturning moment (may capsize).

Neutral Equilibrium: \( M \) coincides with \( G \)

→ No moment is produced.

Thus, for stability, the condition \( \text{Metacentric height} = GM > 0 \) must be satisfied, meaning \( M \) must be above \( G \).

⦾ The correct answer is: B) Metacentre should be above centre of gravity

(A) \( x^2 y = \text{constant} \)

(B) \( xy^2 = \text{constant} \)

(C) \( xy = \text{constant} \)

(D) not possible to determine

Solution =

⦾ Given: A 2D flow field with velocity components:

\[ u = x^2 t, \quad v = -2 x y t \]

To Find: Equation of streamlines.

⦾ Step 1: Use streamline equation

The streamline equation is: \[ \frac{dx}{u} = \frac{dy}{v} \] Substituting the values of \( u \) and \( v \): \[ \frac{dx}{x^2 t} = \frac{dy}{-2 x y t} \]

Cancel the common term \( t \) (assuming \( t \ne 0 \)):

\[ \frac{dx}{x^2} = \frac{dy}{-2 x y} \]

⦾ Step 2: Cross multiply and simplify

Multiply both sides by \( x^2 \cdot (-2 x y) \): \[ (-2 x y) \, dx = x^2 \, dy \] \[ -2 y \, dx = x \, dy \]

⦾ Step 3: Separate variables and integrate

\[ \frac{dy}{y} = -2 \frac{dx}{x} \] Integrating both sides: \[ \ln y = -2 \ln x + \ln C \] Using log properties: \[ \ln y + 2 \ln x = \ln C \]\[\Rightarrow \quad \ln (x^2 y) = \ln C \] \[ x^2 y = \text{constant} \]

⦾ Final Answer:

\[ \boxed{x^2 y = \text{constant}} \quad \text{(Option A)} \]

(A) \( \frac{\partial v}{\partial x} \)

(B) \( -\frac{\partial v}{\partial x} \)

(C) \( \frac{\partial v}{\partial y} \)

(D) \( -\frac{\partial v}{\partial y} \)

Solution =

Concept: For a two-dimensional potential flow, the flow is incompressible and irrotational.

We use two important conditions:

1. Continuity equation for incompressible flow:

\[ \frac{\partial u}{\partial x} + \frac{\partial v}{\partial y} = 0 \Rightarrow \frac{\partial u}{\partial x} = -\frac{\partial v}{\partial y} \]

So the correct answer is:

\[ \boxed{D\ \left(-\frac{\partial v}{\partial y}\right)} \]

(A) Francis

(B) Kaplan

(C) Pelton

(D) Propeller

Solution =

⦾ Given:

✓ \( H = 24.5 \, \text{m} \)

✓ \( Q = 10.1 \, \text{m}^3/\text{s} \)

✓ \( N = 4.0 \, \text{rps} = 4 \times 60 = 240 \, \text{rpm} \)

✓ \( \eta = 90\% = 0.9 \)

⦾ Step 1: Compute Power Output

\[ P = \eta \cdot \rho g Q H \]\[= 0.9 \cdot 1000 \cdot 9.81 \cdot 10.1 \cdot 24.5 \] \[ P \approx 0.9 \cdot 1000 \cdot 9.81 \cdot 247.45 \]\[= 0.9 \cdot 1000 \cdot 2427.6 \approx 2184840 \, \text{W} \] \[ P \approx 2184.84 \, \text{kW} \]

⦾ Step 2: Use the Specific Speed Formula

\[ N_s = \frac{N \sqrt{P}}{H^{5/4}} = \frac{240 \cdot \sqrt{2184.84}}{(24.5)^{1.25}} \]\[= \frac{240 \cdot 46.74}{(24.5)^{1.25}} \approx \frac{11217.6}{61.43} \approx 182.6 \]

⦾ Step 3: Turbine Type Based on Specific Speed

✓ Pelton: \( N_s = 10 \)–\( 35 \)

✓ Francis: \( N_s = 60 \)–\( 250 \)

✓ Kaplan: \( N_s = 250 \)–\( 850 \)

✓ Propeller: \( N_s > 300 \)

⦾ Final Answer:

Since \( N_s \approx 183 \), the suitable turbine is: \[ \boxed{\text{A — Francis}} \]

(A) 0.1

(B) 1

(C) 10

(D) 100

Solution =

⦾ Understanding the Problem

We have a scale model experiment where:

✓ Length scale ratio (\(L_r\)) = \(\frac{L_p}{L_m} = 100\)

✓ Model velocity (\(V_m\)) = \(1 \, \text{ms}^{-1}\)

We need to find the prototype velocity (\(V_p\)) while maintaining Froude number similarity.

⦾ Froude Number Similarity

The Froude number (\(Fr\)) is given by:

\[ Fr = \frac{V}{\sqrt{gL}} \] For dynamic similarity, the Froude number must be the same in both model and prototype:

\[ Fr_m = Fr_p \] \[ \frac{V_m}{\sqrt{gL_m}} = \frac{V_p}{\sqrt{gL_p}} \] ⦾ Velocity Scale Relationship

Since gravitational acceleration (\(g\)) cancels out:

\[ \frac{V_m}{\sqrt{L_m}} = \frac{V_p}{\sqrt{L_p}} \] The velocity scale ratio (\(V_r\)) is therefore:

\[ V_r = \frac{V_p}{V_m} = \sqrt{\frac{L_p}{L_m}} = \sqrt{L_r} \] Given \(L_r = 100\):

\[ V_r = \sqrt{100} = 10 \] ⦾ Calculating Prototype Velocity

Using the velocity scale ratio:

\[ V_p = V_r \times V_m = 10 \times 1 \, \text{ms}^{-1} = 10 \, \text{ms}^{-1} \] ⦾ Conclusion

The correct prototype velocity is \(10 \, \text{ms}^{-1}\), which corresponds to option C.

⦾ Final Answer: \(\boxed{C}\)

(A) \( V_2 > V_1 \)

(B) \( V_2 = V_1 \)

(C) \( V_2 < V_1 \)

(D) Insufficient data to definitively conclude the relationship between \( V_1 \) and \( V_2 \)

Solution =

Using Torricelli’s Law, the exit velocity of a fluid from a hole under the force of gravity is given by:

$$ V = \sqrt{2gh} $$

⦾ Where:

✓ \( g \) = acceleration due to gravity

✓ \( h \) = height of the fluid column above the hole

However, Torricelli’s Law assumes the fluid is ideal and incompressible. Practically, the pressure at the hole is due to hydrostatic pressure:

$$ P = \rho g h $$

⦾ Where:

✓ \( P \) = hydrostatic pressure

✓ \( \rho \) = fluid density

Thus, the velocity of efflux can also be expressed as:

$$ V = \sqrt{\frac{2P}{\rho}} = \sqrt{2gh} $$

Since both tanks have the same fluid height \( h \) and experience gravity equally, in ideal conditions, both would have the same exit velocity:

$$ V_1 = V_2 $$

However, considering real-world behavior:

Engine oil has a lower density than water.

This results in lower hydrostatic pressure at the same height.

Therefore:

$$ P_{\text{oil}} < P_{\text{water}} $$

Leading to:

$$ V_2 < V_1 $$

Hence, the fluid with higher density (water) will have a higher exit velocity.

⦾ Final Answer: Option C. \( V_2 < V_1 \)

(A) Kaplan, Francis, Pelton

(B) Pelton, Francis, Kaplan

(C) Francis, Kaplan, Pelton

(D) Pelton, Kaplan, Francis

Solution =

In hydraulic turbines, the flow rate handling capacity generally depends on the type of turbine. Based on common design practices, the descending order of flow rate capacity is:

Kaplan > Francis > Pelton

This is because:

✓ Kaplan turbine: Axial flow turbine used for low head and high flow applications.

✓ Francis turbine: Mixed flow turbine suitable for medium head and moderate flow.

✓ Pelton turbine: Impulse turbine used for high head and low flow applications.

So, the correct descending order of flow rate is:

Kaplan > Francis > Pelton

(A) The rotor blade is symmetric.

(B) The stator blade is symmetric.

(C) The absolute inlet flow angle is equal to absolute exit flow angle.

(D) The absolute exit flow angle is equal to inlet angle of rotor blade.

Solution =

In a 50% reaction stage, the steam pressure drop is equally divided between the stator and rotor blades, meaning the energy transfer to the fluid is the same in both stages. This symmetry leads to the absolute exit flow angle from the rotor being equal to the inlet angle of the rotor blade.

⦾ Why other options are incorrect:

✓ The rotor blade is symmetric:

While the blade design might be symmetrical in some 50% reaction turbines, this is not the defining characteristic of the reaction stage itself.

✓ The stator blade is symmetric:

Similar to the rotor blade, symmetry in the stator blade is not the defining feature of a 50% reaction stage.

✓ The absolute inlet flow angle is equal to absolute exit flow angle:

This statement describes the condition for a fully symmetrical turbine, but in a 50% reaction turbine, only the absolute exit flow angle is equal to the rotor blade inlet angle.

(A) unsteady and one-dimensional

(B) steady and two-dimensional

(C) steady and one-dimensional

(D) unsteady and two-dimensional

Solution =

⦾ Given Position Equations:

\[ x = x_0 e^{-kt}, \quad y = y_0 e^{kt} \] where:

\(x_0\), \(y_0\), and \(k\) are constants,

\(t\) is time.

⦾ Step 1: Check for Time Dependence (Steady vs. Unsteady)

The equations for \(x\) and \(y\) explicitly depend on time \(t\) (through the terms \(e^{-kt}\) and \(e^{kt}\)).

Conclusion: The flow is unsteady because the particle’s position changes with time.

⦾ Step 2: Check the Dimensionality (1D vs. 2D)

The flow is described by two independent coordinates: \(x\) and \(y\).

Both coordinates are functions of time, and neither can be eliminated or expressed purely in terms of the other.

Conclusion: The flow is two-dimensional because it requires both \(x\) and \(y\) to describe the motion.

⦾ Step 3: Given Options

✓ Option A: Unsteady and one-dimensional → Incorrect (the flow is 2D).

✓ Option B: Steady and two-dimensional → Incorrect (the flow is unsteady).

✓ Option C: Steady and one-dimensional → Incorrect (both properties are wrong).

✓ Option D: Unsteady and two-dimensional → Correct.

⦾ Final Answer: D) The flow is unsteady and two-dimensional.

(A) 4

(B) 2

(C) 0.5

(D) 0.25

Solution =

To solve this, we use the relationship between boundary layer thickness \( \delta \), Reynolds number \( Re \), and flow velocity \( U \) for a flat plate with zero pressure gradient:

⦾ Formula:

\[ \delta \propto \frac{x}{\sqrt{Re_x}} \quad \text{where} \quad Re_x = \frac{Ux}{\nu} \]

So,

\[ \delta \propto \frac{1}{\sqrt{U}} \quad \text{(since \(x\) and \( \nu \) are constant)} \]

⦾ Given:

✓ Initial Reynolds number: \( Re_1 = 1000 \)

✓ Initial boundary layer thickness: \( \delta_1 = 1 \, \text{mm} \)

Velocity increases by a factor of 4: \( U_2 = 4U_1 \)

So,

\[ \delta_2 = \delta_1 \cdot \frac{1}{\sqrt{4}} = 1 \cdot \frac{1}{2} = 0.5 \, \text{mm} \]

⦾ Correct Answer: C) 0.5

(A) 1.8

(B) 17.4

(C) 20.5

(D) 41

Solution =

⦾ We are given:

✓ Length of pipe: \( L = 1.0 \, \text{km} = 1000 \, \text{m} \)

✓ Diameter of pipe: \( D = 200 \, \text{mm} = 0.2 \, \text{m} \)

✓ Flow rate: \( Q = 0.07 \, \text{m}^3/\text{s} \)

✓ Darcy friction factor: \( f = 0.02 \)

✓ Density of water: \( \rho = 1000 \, \text{kg/m}^3 \)

We need to calculate the pumping power required to overcome frictional head loss.

⦾ Step 1: Velocity of flow

\[ A = \frac{\pi D^2}{4} = \frac{\pi (0.2)^2}{4} = 0.0314 \, \text{m}^2 \] \[ V = \frac{Q}{A} = \frac{0.07}{0.0314} \approx 2.23 \, \text{m/s} \] ⦾ Step 2: Head loss due to friction (Darcy-Weisbach equation)

\[ h_f = f \cdot \frac{L}{D} \cdot \frac{V^2}{2g} \] \[ h_f = 0.02 \cdot \frac{1000}{0.2} \cdot \frac{(2.23)^2}{2 \cdot 9.81} \]\[= 0.02 \cdot 5000 \cdot \frac{4.97}{19.62} \approx 100 \cdot 0.2534 \]\[= 25.34 \, \text{m} \] ⦾ Step 3: Pumping power required

\[ P = \rho g Q h_f = 1000 \cdot 9.81 \cdot 0.07 \cdot 25.34 \]\[\approx 17390.4 \, \text{W} = 17.4 \, \text{kW} \] ⦾ Final Answer: Option B: 17.4 kW

(A) 7.5 kW

(B) 15.0 kW

(C) 22.5 kW

(D) 37.5 kW

Solution =

To solve this Pelton wheel problem, we’ll use the power developed by the jet on the Pelton wheel formula for ideal flow:

⦾ Given:

✓ Bucket peripheral speed, \( u = 10\ \text{m/s} \)

✓ Jet velocity, \( V = 25\ \text{m/s} \)

✓ Volumetric flow rate, \( Q = 0.1\ \text{m}^3/\text{s} \)

✓ Jet deflection angle, \( \theta = 120^\circ \)

Ideal flow (no losses)

⦾ Formula for power developed:

\[ P = \rho Q (V – u) \left(1 + \cos\theta\right) u \]

Where:

\( \rho = 1000\ \text{kg/m}^3 \) (density of water)

\( \theta = 120^\circ \Rightarrow \cos(120^\circ) = -0.5 \)

Substitute values:

\[ P = 1000 \times 0.1 \times (25 – 10) \]\[\times (1 – 0.5) \times 10 \]

\[ P = 1000 \times 0.1 \times 15 \times 0.5 \times 10 \]\[= 7500\ \text{W} = 7.5\ \text{kW} \]

⦾ Final Answer: (A) 7.5 kW

(A) always isentropic

(B) always choked

(C) never choked

(D) never isentropic

Solution =

A convergent-divergent (C-D) nozzle, also known as a De Laval nozzle, is used to accelerate fluids (typically gases) to supersonic speeds. When it is correctly designed and operating at design conditions, the flow behaves as follows:

The throat (the narrowest section) is where the flow becomes sonic, i.e., the Mach number \( M = 1 \). This is called the choked condition.

In the divergent section, the flow expands and accelerates to supersonic speeds, i.e., \( M > 1 \).

A “designed load” means the nozzle operates under specific pressure conditions such that the exit pressure equals the ambient (back) pressure.

Under these conditions, choking always occurs at the throat, ensuring proper acceleration through the nozzle.

⦾ Why not the other options?

✓ A) always isentropic: Not necessarily. Although design conditions aim for isentropic flow, real conditions may introduce friction or shocks.

✓ C) never choked: Incorrect. At design conditions, the flow must be choked at the throat.

✓ D) never isentropic: Incorrect. The flow can be isentropic if there are no shocks or dissipative effects.

(A) a reduction of pressure to vapour pressure

(B) a negative pressure gradient

(C) a positive pressure gradient

(D) the boundary layer thickness reducing to zero

Solution =

Flow separation occurs when the fluid particles near a surface reverse direction and detach from the surface. This typically happens due to an adverse pressure gradient, which means the pressure is increasing in the direction of the flow.

⦾ Key Concepts:

A positive pressure gradient means:

\[ \frac{dp}{dx} > 0 \] i.e., pressure increases in the flow direction.

As the fluid moves from a region of low pressure to high pressure, the kinetic energy decreases since some of it is used to overcome the pressure rise.

In the boundary layer, where the fluid has already been slowed by viscosity, this loss of energy causes the flow to reverse direction, leading to separation.

⦾ Why the other options are incorrect:

✓ A) a reduction of pressure to vapour pressure → This causes cavitation, not flow separation.

✓ B) a negative pressure gradient → This helps the flow stay attached by accelerating it.

✓ D) the boundary layer thickness reducing to zero → This does not lead to separation. In fact, separation is associated with the boundary layer thickening.

⦾ Correct Answer: C) a positive pressure gradient

(A) 1

(B) 2

(C) 3

(D) 4

Solution =

⦾ Step 1: Apply Incompressibility Condition

For an incompressible flow, the divergence of velocity must be zero:

\[ \nabla \cdot \vec{V} = 0 \] \[ \frac{\partial u}{\partial x} + \frac{\partial v}{\partial y} = 0 \] Given \(u = 2\sinh x\), we compute its derivative:

\[ \frac{\partial u}{\partial x} = 2\cosh x \] Thus, the y-component must satisfy: \[ \frac{\partial v}{\partial y} = -2\cosh x \]

⦾ Step 2: Integrate to Find v(x,y)

Integrate with respect to y:

\[ v(x,y) = -2\cosh x \cdot y + f(x) \] Where \(f(x)\) is an integration constant that may depend on x.

⦾ Step 3: Apply Boundary Condition

Given \(v(x,0) = \cosh x\):

\[ \cosh x = -2\cosh x \cdot 0 + f(x) \Rightarrow f(x) \]\[= \cosh x \] Thus, the complete expression for v(x,y) is: \[ v(x,y) = -2y\cosh x + \cosh x \]\[= \cosh x (1 – 2y) \]

⦾ Step 4: Evaluate at (0,-1)

Compute \(v(0,-1)\):

\[ v(0,-1) = \cosh 0 (1 – 2(-1)) \]\[= 1 \times (1 + 2) = 3 \] Note that \(\cosh 0 = 1\).

⦾ Final Answer: \(\boxed{C}\)

(A) Since volume flow rate is constant, velocity at B is lower than velocity at A

(B) Normal shock

(C) Viscous effect

(D) Boundary layer separation

Solution =

⦾ Key Concepts:

1. Supersonic flow in divergent channels behaves differently than subsonic flow

2. Pressure increases when supersonic flow decelerates (contrary to subsonic behavior)

3. Shock waves can cause sudden pressure increases

⦾ Option A Analysis:

“Volume flow rate constant → lower velocity at B”

– For supersonic flow in a divergent channel: – Area ↑ → Velocity ↑ (opposite to subsonic behavior) – Pressure actually increases when velocity decreases in supersonic flow – However, the argument about volume flow rate alone doesn’t explain the pressure rise mechanism. Not the best answer.

⦾ Option B Analysis:

“Normal shock”

– A normal shock causes: – Sudden transition from supersonic to subsonic flow – Large pressure increase (while decreasing velocity) – Exactly matches the observed phenomenon – This is the correct explanation.

⦾ Option C Analysis:Viscous effect

– Viscosity causes gradual pressure losses – Cannot explain sudden pressure increase – Incorrect.

⦾ Option D Analysis:

“Boundary layer separation”

– Separation causes pressure recovery, but: – Typically occurs downstream of shocks – Not the primary cause of pressure increase in supersonic flow – Secondary effect, not main reason.

⦾ Final Answer: The pressure increase is caused by a normal shock. \(\boxed{B}\)

(A) Both Pelton and Francis turbines are impulse turbines.

(B) Francis turbine is a reaction turbine but Kaplan turbine is an impulse turbine.

(C) Francis turbine is an axial’flow reaction turbine.

(D) Kaplan turbine is an axial’flow reaction turbine.

Solution =

⦾ Let’s analyze each statement about turbine types:

✓ A. Both Pelton and Francis turbines are impulse turbines.

This is FALSE because:

Pelton turbine is an impulse turbine (uses jet of water impacting buckets)

Francis turbine is a reaction turbine (water pressure changes through the turbine)

✓ B. Francis turbine is a reaction turbine but Kaplan turbine is an impulse turbine.

This is FALSE because:

Francis turbine is correctly identified as reaction turbine

But Kaplan turbine is also a reaction turbine (not impulse)

✓ C. Francis turbine is an axial-flow reaction turbine.

This is FALSE because:

Francis turbine is a radial/centripetal-flow reaction turbine

Axial-flow refers to turbines where water flows parallel to the axis (like Kaplan)

✓ D. Kaplan turbine is an axial-flow reaction turbine.

This is TRUE because:

Kaplan turbine is indeed a reaction turbine (pressure changes through runner)

It has axial-flow design (water flows parallel to the axis of rotation)

Adjustable blades make it suitable for low-head, high-flow situations

⦾ Conclusion:

The TRUE statement is: D. Kaplan turbine is an axial-flow reaction turbine.

(A) Centrifugal pump

(B) Gear pump

(C) Jet pump

(D) vane

Solution =

We need to identify which of the given options is not a rotating machine. Let’s analyze each option:

✓ A. Centrifugal pump

This is a rotating machine. It uses an impeller (rotating component) to increase the pressure of the fluid.

✓ B. Gear pump

This is a rotating machine. It uses meshing gears to pump fluid by displacement.

✓ C. Jet pump

This is not a rotating machine. It works on the principle of fluid dynamics (Venturi effect) without any rotating parts.

✓ D. Vane pump

This is a rotating machine. It uses rotating vanes to pump fluids.

⦾ Conclusion: The correct answer is: \[ \boxed{C\ \text{Jet pump}} \]

(A) It increases until the flow is fully developed.

(B) It is constant and is eaual to the average velocity in the fully devloped region.

(C) It decreases until the flow is fully developed

(D) It is constant but is always lower than the average velocity in the fully developed region.

Solution =

⦾ Solution: For steady flow of a viscous incompressible fluid through a circular pipe:

⦾ Key Concepts:

✓ In the developing region (entrance length), the velocity profile evolves from a uniform profile to a parabolic profile

✓ In the fully developed region, the velocity profile becomes parabolic and remains unchanged

✓ Due to continuity (conservation of mass), the average velocity remains constant throughout the pipe

⦾ Analysis of Options:

A. It increases until the flow is fully developed

Incorrect – The average velocity doesn’t increase

B. It is constant and equal to the average velocity in the fully developed region

Correct – Conservation of mass requires the average velocity to remain constant

C. It decreases until the flow is fully developed

Incorrect – The average velocity doesn’t decrease

D. It is constant but is always lower than the average velocity in the fully developed region

Incorrect – The average velocity is equal in both regions

⦾ Conclusion: The correct statement is B: It is constant and is equal to the average velocity in the fully developed region

(A) 116.18

(B) 0.116

(C) 18.22

(D) 232.36

Solution =

⦾ Given:

✓ Diameter \( D = 200 \, \text{mm} = 0.2 \, \text{m} \)

✓ Length \( L = 500 \, \text{m} \)

✓ Friction factor \( f = 0.0225 \)

✓ Flow rate \( Q = 0.2 \, \text{m}^3/\text{s} \)

✓ Acceleration due to gravity \( g = 9.81 \, \text{m/s}^2 \)

We need to calculate head loss due to friction using the Darcy-Weisbach equation:

\[ h_f = \frac{f L v^2}{D \cdot 2g} \]

⦾ Step 1: Calculate cross-sectional area

\[ A = \frac{\pi D^2}{4} = \frac{\pi (0.2)^2}{4} = 0.0314 \, \text{m}^2 \]

⦾ Step 2: Calculate velocity

\[ v = \frac{Q}{A} = \frac{0.2}{0.0314} \approx 6.369 \, \text{m/s} \]

⦾ Step 3: Plug into the Darcy-Weisbach equation

\[ h_f = \frac{0.0225 \cdot 500 \cdot (6.369)^2}{0.2 \cdot 2 \cdot 9.81} \]

\[ h_f = \frac{0.0225 \cdot 500 \cdot 40.56}{3.924} \]

\[ h_f \approx \frac{456.3}{3.924} \approx 116.3 \, \text{m} \]

⦾ Final Answer: A) 116.18

(A) P and R

(B) Q

(C) Q and R

(D) R

Solution =

⦾ Incompressibility condition:

\[ \frac{\partial u}{\partial x} + \frac{\partial v}{\partial y} = 0 \]

⦾ Irrotationality condition (2D):

\[ \frac{\partial v}{\partial x} – \frac{\partial u}{\partial y} = 0 \]

Option P: \( u = 2y, \, v = -3x \)

Incompressibility: \( \frac{\partial u}{\partial x} = 0, \, \frac{\partial v}{\partial y} = 0 \Rightarrow 0 + 0 = 0 \quad \text{✅} \)

Irrotationality: \( \frac{\partial v}{\partial x} = -3, \, \frac{\partial u}{\partial y} = 2 \)\(\Rightarrow -3 – 2 = -5 \quad \text{❌} \)

Option Q: \( u = 3xy, \, v = 0 \)

Incompressibility: \( \frac{\partial u}{\partial x} = 3y, \, \frac{\partial v}{\partial y} = 0 \Rightarrow 3y \neq 0 \quad \text{❌} \)

Irrotationality: \( \frac{\partial v}{\partial x} = 0, \, \frac{\partial u}{\partial y} = 3x \)\(\Rightarrow -3x \neq 0 \quad \text{❌} \)

Option R: \( u = -2x, \, v = 2y \)

Incompressibility: \( \frac{\partial u}{\partial x} = -2, \, \frac{\partial v}{\partial y} = 2 \)\(\Rightarrow -2 + 2 = 0 \quad \text{✅} \)

Irrotationality: \( \frac{\partial v}{\partial x} = 0, \, \frac{\partial u}{\partial y} = 0 \)\(\Rightarrow 0 – 0 = 0 \quad \text{✅} \)

⦾ Correct Answer: Option D — R

(A) 2.34

(B) 4.68

(C) 9.38

(D) 18.75

Solution =

⦾ Given Parameters:

Prototype Turbine:

✓ Power: \( P_{\text{prototype}} = 300 \, \text{kW} \)

✓ Head: \( H_{\text{prototype}} = 40 \, \text{m} \)

✓ Speed: \( N_{\text{prototype}} = 1000 \, \text{rpm} \)

✓ Model Turbine: Scale ratio: \( \frac{D_{\text{model}}}{D_{\text{prototype}}} = \frac{1}{4} \)

✓ Head: \( H_{\text{model}} = 10 \, \text{m} \)

⦾ Solution:

The power similarity law for hydraulic turbines is: \[ \frac{P_{\text{model}}}{P_{\text{prototype}}} \]\[= \left( \frac{H_{\text{model}}}{H_{\text{prototype}}} \right)^{3/2} \times \left( \frac{D_{\text{model}}}{D_{\text{prototype}}} \right)^2 \]

⦾ Step 1: Substitute the given values \[ \frac{P_{\text{model}}}{300} = \left( \frac{10}{40} \right)^{3/2} \times \left( \frac{1}{4} \right)^2 \]

⦾ Step 2: Simplify the equation \[ \frac{P_{\text{model}}}{300} = \left( \frac{1}{4} \right)^{3/2} \times \left( \frac{1}{16} \right) \] \[ \frac{P_{\text{model}}}{300} = \left( \frac{1}{8} \right) \times \left( \frac{1}{16} \right) = \frac{1}{128} \]

⦾ Step 3: Solve for model power \[ P_{\text{model}} = \frac{300}{128} = 2.34375 \, \text{kW} \]

⦾ Step 4: Round the result \[ P_{\text{model}} \approx 2.34 \, \text{kW} \]

⦾ Final Answer: The power generated by the model turbine is 2.34 kW, which corresponds to option A.

(A) \( \frac{2Q(R_1 – R_2)}{\pi L R_2^3} \)

(B) \( \frac{2Q^2(R_1 – R_2)}{\pi L R_2^3} \)

(C) \( \frac{2Q^2(R_1 – R_2)}{\pi^2 L R_2^5} \)

(D) \( \frac{2Q^2(R_2 – R_1)}{\pi^2 L R_2^5} \)

Solution =

⦾ Given:

✓ Length of pipe: \( L \)

✓ Inlet radius: \( R_1 \), Outlet radius: \( R_2 \)

✓ Constant flow rate: \( Q \)

Axial and uniform velocity at all cross-sections

⦾ Step-by-Step Solution:

Velocity at any cross-section: \[ v = \frac{Q}{A} = \frac{Q}{\pi R^2} \] At the exit (radius \( R_2 \)): \[ v = \frac{Q}{\pi R_2^2} \]

Acceleration Along the Axis:

Using material derivative: \[ a = \frac{dv}{dt} = v \frac{dv}{dx} \] Let the radius vary linearly from \( R_1 \) to \( R_2 \) over the length \( L \): \[ R(x) = R_1 + \left( \frac{R_2 – R_1}{L} \right) x \] Then, \[ v(x) = \frac{Q}{\pi R(x)^2} \]\[ \Rightarrow \frac{dv}{dx} = \frac{d}{dx} \left( \frac{Q}{\pi R(x)^2} \right) = \frac{-2Q}{\pi R^3} \cdot \frac{dR}{dx} \] Since \[ \frac{dR}{dx} = \frac{R_2 – R_1}{L} \] At the exit (\( R = R_2 \)):

⦾ Acceleration at the Exit:

\[ a = v \cdot \frac{dv}{dx} \]\[ = \left( \frac{Q}{\pi R_2^2} \right) \cdot \left( \frac{-2Q}{\pi R_2^3} \cdot \frac{R_2 – R_1}{L} \right) \]\[ = \frac{-2Q^2 (R_2 – R_1)}{\pi^2 L R_2^5} \] Taking the magnitude (acceleration is opposite to flow direction): \[ a = \boxed{ \frac{2Q^2 (R_1 – R_2)}{\pi^2 L R_2^5} } \]

⦾ Correct Option: C

(A) m + n

(B) m * n

(C) m – n

(D) m / n

Solution =

⦾ Explanation:

This question is based on the Buckingham Pi Theorem, a key principle in dimensional analysis.

⦾ Buckingham Pi Theorem:

If a physical problem involves:

\( m \) physical quantities

\( n \) fundamental dimensions (e.g., mass, length, time, temperature, etc.)

Then, the number of independent non-dimensional parameters (also called \( \pi \) terms) that describe the system is:

\[ \boxed{m – n} \] ⦾ Example:

✓ \( m = 5 \) physical quantities

✓ \( n = 3 \) fundamental dimensions (e.g., M, L, T)

Then the number of dimensionless parameters is:

\[ 5 – 3 = 2 \]

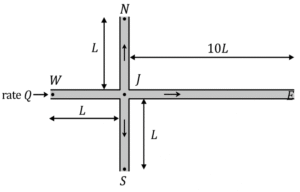

I. The flow rate in pipe connecting J and E is Q/21.

II. The pressure difference between J and N is equal to the pressure difference between J and E.

Which one of the following options is CORRECT?

(Q) = Flow Rate

(A) I is True and II is False

(B) I is False and II is True

(C) Both I and II are True

(D) Both I and II are False

Solution =

⦾ Flow Network Analysis:

The total flow rate entering at \( W \) is:

$$ Q $$

At junction \( J \), the flow splits towards \( N \), \( S \), and \( E \).

⦾ Head Loss Relationship:

The head loss (\( h_f \)) due to friction in a pipe is given by:

$$ h_f \propto f \cdot \frac{L}{D} \cdot \frac{v^2}{2g} $$

Since cross-section and friction factor are equal for all pipes, the head loss is directly proportional to:

$$ h_f \propto L \cdot Q^2 $$

⦾ Considering length:

✓ Pipes \( JN \), \( JS \), and \( JW \) have length \( L \)

✓ Pipe \( JE \) has length \( 10L \)

Therefore, pipe \( JE \) offers significantly higher resistance compared to the other three.

⦾ Flow Division:

Since the path to \( E \) has 10 times longer length, only a small portion of flow will go towards \( E \). Therefore, the claim in statement I, that flow in \( JE \) is \( Q/21 \), is incorrect without detailed calculation. The actual flow would be very small but not exactly \( Q/21 \).

⦾ Pressure Difference:

At steady state, due to equal pressure at ends \( N \), \( E \), and \( S \), and same flow division symmetry from \( J \), the pressure drop between \( J \) to \( N \) will be equal to the pressure drop from \( J \) to \( E \), as both are determined by frictional resistance from junction \( J \) to the endpoints, though flows differ.

Thus, statement II is correct.

⦾ Final Answer: Option B: I is False and II is True

(A) 350π²

(B) 750π

(C) 1000π

(D) 3000

Solution =

⦾ Given:

✓ Diameter (D) = 1 m → Area (A) = π(0.5)² = π/4 m²

✓ Upstream: ρ₁ = 1 kg/m³, V₁ = 100 m/s

✓ Downstream: V₂ = 170 m/s

✓ Pressure drop (P₁ – P₂) = 10 kPa = 10,000 Pa

⦾ Step 1: Apply Continuity Equation

For steady flow, mass flow rate (ṁ) is constant: \[ ṁ = ρ₁AV₁ = ρ₂AV₂ \] \[ 1 \times \frac{π}{4} \times 100 = ρ₂ \times \frac{π}{4} \times 170 \] \[ ρ₂ = \frac{100}{170} = 0.588 \text{ kg/m³} \]

⦾ Step 2: Apply Momentum Equation

Force balance in x-direction: \[ F = ṁ(V₂ – V₁) + (P₂A – P₁A) \] Substitute ṁ = ρ₁AV₁ = 1 × (π/4) × 100 = 25π kg/s: \[ F = 25π(170 – 100) + \left(P₂\frac{π}{4} – P₁\frac{π}{4}\right) \] Given P₁ – P₂ = 10,000 Pa: \[ F = 25π \times 70 – 10,000 \times \frac{π}{4} \] \[ F = 1750π – 2500π = -750π \text{ N} \]

⦾ Step 3: Interpret the Force

The negative sign indicates the force is exerted by the gas on the pipe in the opposite direction. Thus, magnitude is: \[ |F| = 750π \text{ N} \]

⦾ Final Answer: The force exerted by the gas on the pipe is \(\boxed{B}\) \(750π\) N.

(A) 2

(B) 1

(C) 2√5

(D) 0

Solution =

Given the velocity field for steady flow: \[ \overrightarrow{v} = (-x^2 + 3y)\hat{i} + (2xy)\hat{j} \]

We need to find the acceleration magnitude at point (1, -1).

⦾ Step 1: Calculate acceleration components

For steady flow, particle acceleration is given by: \[ \overrightarrow{a} = (\overrightarrow{v} \cdot \nabla)\overrightarrow{v} \] Which expands to: \[ a_x = u\frac{\partial u}{\partial x} + v\frac{\partial u}{\partial y} \] \[ a_y = u\frac{\partial v}{\partial x} + v\frac{\partial v}{\partial y} \]

Where: \[ u = -x^2 + 3y, \quad v = 2xy \]

Compute partial derivatives: \[ \frac{\partial u}{\partial x} = -2x, \quad \frac{\partial u}{\partial y} = 3 \] \[ \frac{\partial v}{\partial x} = 2y, \quad \frac{\partial v}{\partial y} = 2x \]

Now calculate acceleration components: \[ a_x = (-x^2 + 3y)(-2x) + (2xy)(3) \] \[ a_y = (-x^2 + 3y)(2y) + (2xy)(2x) \]

⦾ Step 2: Evaluate at point (1, -1)

Substitute x = 1, y = -1: \[ u = -(1)^2 + 3(-1) = -1 -3 = -4 \] \[ v = 2(1)(-1) = -2 \]

Compute acceleration components: \[ a_x = (-4)(-2) + (-2)(3) = 8 – 6 = 2 \] \[ a_y = (-4)(-2) + (-2)(2) = 8 – 4 = 4 \]

⦾ Step 3: Calculate magnitude

Acceleration magnitude: \[ |\overrightarrow{a}| = \sqrt{a_x^2 + a_y^2} = \sqrt{2^2 + 4^2} \]\[= \sqrt{4 + 16} = \sqrt{20} = 2\sqrt{5} \]

⦾ Conclusion:

The correct answer is: \[ \boxed{C\ 2\sqrt{5}} \]

(A) \( a_1 + b_1 = 0 \)

(B) \( a_1 + b_2 = 0 \)

(C) \( a_2 + b_2 = 0 \)

(D) \( a_2 + b_1 = 0 \)

Solution =

Given the two-dimensional velocity field: \(\vec{V} = \) \[ (5 + a_1 x + b_1 y)\hat{i} + (4 + a_2 x + b_2 y)\hat{j} \] We need to determine the condition for incompressible flow.

⦾ Step 1: Recall incompressibility condition

For incompressible flow in 2D, the divergence of velocity must be zero: \[ \nabla \cdot \vec{v} = \frac{\partial u}{\partial x} + \frac{\partial v}{\partial y} = 0 \] where \( u = 5 + a_1 x + b_1 y \) and \( v = 4 + a_2 x + b_2 y \).

⦾ Step 2: Compute partial derivatives

Calculate the required derivatives: \[ \frac{\partial u}{\partial x} = a_1 \] \[ \frac{\partial v}{\partial y} = b_2 \]

⦾ Step 3: Apply incompressibility condition

Set the divergence to zero: \[ a_1 + b_2 = 0 \]

⦾ Conclusion:

The correct condition is: \[ \boxed{B\ a_1 + b_2 = 0} \]

1) The flow is incompressible.

2) The flow is unsteady.

3) y-component of acceleration, \( a_y = \frac{-y}{(x^2 + y^2)^2} \)

4) x-component of acceleration, \( a_x = \frac{-(x+y)}{(x^2 + y^2)^2} \)

(A) (2) and (3)

(B) (1) and (3)

(C) (1) and (2)

(D) (3) and (4)

Solution =

Given the two-dimensional velocity field: \[ \vec{u} = \frac{x}{x^2 + y^2} \hat{i} + \frac{y}{x^2 + y^2} \hat{j} \] We need to evaluate each statement.

⦾ Step 1: Check incompressibility (Statement 1)

For incompressible flow, ∇·u = 0: \[ \frac{\partial u_x}{\partial x} + \frac{\partial u_y}{\partial y} \]\[= \frac{y^2 – x^2}{(x^2 + y^2)^2} + \frac{x^2 – y^2}{(x^2 + y^2)^2} = 0 \] Statement 1 is TRUE

⦾ Step 2: Check steadiness (Statement 2)

The velocity field has no time dependence → Statement 2 is FALSE

⦾ Step 3: Calculate y-component acceleration (Statement 3)

Using ay = u·∇uy: \[ a_y = \frac{x}{x^2+y^2}\frac{\partial u_y}{\partial x} + \frac{y}{x^2+y^2}\frac{\partial u_y}{\partial y} \]\[= \frac{-y}{(x^2 + y^2)^2} \] Statement 3 is TRUE

⦾ Step 4: Calculate x-component acceleration (Statement 4)

Similarly: \[ a_x = \frac{x}{x^2+y^2}\frac{\partial u_x}{\partial x} + \frac{y}{x^2+y^2}\frac{\partial u_x}{\partial y} \]\[= \frac{-x}{(x^2 + y^2)^2} \neq \frac{-(x+y)}{(x^2 + y^2)^2} \] Statement 4 is FALSE

⦾ Conclusion:

Correct statements are (1) and (3): \[ \boxed{B\ (1) \text{ and } (3)} \]

(A) Are parallel to each other

(B) Are perpendicular to each other

(C) Intersect at an acute angle

(D) Are identical

Solution =

In fluid mechanics, streamlines represent the direction of fluid flow, while equipotential lines represent locations of equal velocity potential (no change in potential energy).

✓ Streamlines are always tangent to the velocity vector.

✓ Equipotential lines are lines where the velocity potential is constant, and the gradient of velocity potential (which gives the velocity direction) is perpendicular to these lines.

Thus, in irrotational flow fields, streamlines and equipotential lines are always perpendicular at every point.

⦾ Therefore: B) Are perpendicular to each other

P: Shear stress is zero at all points in the flow.

Q: Vorticity is zero at all points in the flow.

R: Velocity is directly proportional to the radius from the centre of the vortex.

S: Total mechanical energy per unit mass is constant in the entire flow field.

(A) P and Q

(B) R and S

(C) P and R

(D) P and S

Solution =

Forced vortex flow: In forced vortex flow, the fluid rotates like a solid body with constant angular velocity \( \omega \). The tangential velocity is given by:

\[ v_\theta = \omega r \]

This shows that the velocity is directly proportional to the radius from the center.

✓ P: Incorrect. In forced vortex, there is a velocity gradient in the tangential direction (\( \frac{dv_\theta}{dr} \neq 0 \)), so shear stress is not zero.

✓ Q: Incorrect. For solid body rotation: \[ \text{Vorticity} = 2\omega \neq 0 \] Therefore, vorticity is not zero.

✓ R: Correct. As shown above, \( v_\theta = \omega r \), hence velocity is directly proportional to radius.

✓ S: Correct. In ideal (non-viscous, incompressible) forced vortex flow, mechanical energy per unit mass remains constant throughout the flow field.

Therefore, the correct combination is: R and S

⦾ Final Answer: Option B

(A) \( \frac{\mu u_0 L}{D^2} \)

(B) \( \frac{4 \mu u_0 L}{D^2} \)

(C) \( \frac{8 \mu u_0 L}{D^2} \)

(D) \( \frac{16 \mu u_0 L}{D^2} \)

Solution =

The velocity profile in fully developed laminar flow in a pipe of diameter \( D \) is:

\[ u(r) = u_0 \left(1 – \frac{4r^2}{D^2}\right) \]

This is a parabolic profile. We are to find the pressure drop \( \Delta P \) across a length \( L \) of the pipe.

⦾ Step 1: Pressure Drop Formula

For laminar flow, the pressure drop is given by:

\[ \Delta P = \frac{32 \mu U_{\text{avg}} L}{D^2} \]

Where:

✓ \( \mu \): fluid viscosity

✓ \( U_{\text{avg}} \): average velocity

✓ \( L \): pipe length

✓ \( D \): pipe diameter

⦾ Step 2: Calculate Average Velocity

Given the velocity profile:

\[ u(r) = u_0 \left(1 – \frac{4r^2}{D^2} \right) \]

Average velocity is defined as:

\[ U_{\text{avg}} = \frac{2}{R^2} \int_0^R u(r) \cdot r \, dr \]

Let \( R = \frac{D}{2} \). Then:

\[ U_{\text{avg}} = \frac{2 u_0}{R^2} \int_0^R \left( r – \frac{4r^3}{D^2} \right) dr \]

Evaluate the integral:

\[ \int_0^R \left( r – \frac{4r^3}{D^2} \right) dr \]\[= \left[ \frac{r^2}{2} – \frac{r^4}{D^2} \right]_0^R = \frac{R^2}{2} – \frac{R^4}{D^2} \]

Now substitute into the average velocity expression:

\[ U_{\text{avg}} = \frac{2u_0}{R^2} \left( \frac{R^2}{2} – \frac{R^4}{D^2} \right) \]\[= u_0 \left(1 – \frac{2R^2}{D^2} \right) \]

Since \( R = \frac{D}{2} \), we get:

\[ U_{\text{avg}} = u_0 \left(1 – \frac{2(D^2/4)}{D^2} \right) \]\[= u_0 \left(1 – \frac{1}{2} \right) = \frac{u_0}{2} \]

⦾ Step 3: Final Pressure Drop

\[ \Delta P = \frac{32 \mu U_{\text{avg}} L}{D^2} = \frac{32 \mu (u_0 / 2) L}{D^2} \]\[= \frac{16 \mu u_0 L}{D^2} \]

⦾ Final Answer:

\[ \boxed{\Delta P = \frac{16 \mu u_0 L}{D^2}} \]

Correct option: D

(A) \( x – 2y = 0 \)

(B) \( 2x + y = 0 \)

(C) \( 2x – y = 0 \)

(D) \( x + 2y = 0 \)

Solution =

Given velocity field:

\[ \vec{V} = ax\,\hat{i} + ay\,\hat{j} \]

The equation for a streamline is:

\[ \frac{dx}{u} = \frac{dy}{v} \]

Substitute \( u = ax \), \( v = ay \):

\[ \frac{dx}{ax} = \frac{dy}{ay} \Rightarrow \frac{dx}{x} = \frac{dy}{y} \]

Integrate both sides:

\[ \int \frac{dx}{x} = \int \frac{dy}{y} \Rightarrow \ln|x| = \ln|y| + C \]\[\Rightarrow \ln\left(\frac{x}{y}\right) = C \]\[\Rightarrow \frac{x}{y} = K \quad \text{(where } K = e^C \text{)} \Rightarrow x = Ky \]

Use the point \( (1, 2) \) to find \( K \):

\[ 1 = K \cdot 2 \Rightarrow K = \frac{1}{2} \Rightarrow x = \frac{1}{2} y \]\[\Rightarrow 2x = y \Rightarrow 2x – y = 0 \]

⦾ Final Answer:

\[ \boxed{2x – y = 0} \] (Correct Option: C)

(A) non-zero normal and shear stress

(B) negative normal stress and zero shear stress

(C) positive normal stress and zero shear stress

(D) zero normal stress and non-zero shear stress

Solution =

In a static fluid (i.e., fluid at rest), the stress behavior is governed by basic fluid mechanics principles:

⦾ Key Points:

A fluid at rest cannot resist shear stress — any shear stress will cause it to deform (flow).

→ So, shear stress = 0

The only stress a static fluid can exert is normal stress, and this is simply the fluid pressure acting perpendicular to any surface in contact with the fluid.

Pressure is a positive normal stress (compressive).

→ Hence, non-zero normal stress can exist in the form of positive pressure.

⦾ Therefore:

Normal stress: Present (as pressure), and it’s positive

Shear stress: Always zero in a static fluid

❌ Why other options are incorrect:

✓ A) Non-zero shear stress is not possible in a static fluid.

✓ B) Fluids cannot have negative pressure under normal circumstances, and shear stress must be zero.

✓ D) Zero normal stress is incorrect — fluids always exert pressure.

⦾ Final Answer: C) positive normal stress and zero shear stress

(A) \(10\hat{i}\)

(B) \(20\hat{j}\)

(C) \(-6\hat{i} – 6\hat{j}\)

(D) \(-4\hat{i} – 4\hat{j}\)

Solution =

Step 1: Understand the Euler Equation

For inviscid flow (μ=0) with negligible body forces, the momentum equation reduces to Euler’s equation:

\[ \rho \frac{D\vec{V}}{Dt} = -\nabla p \] For steady flow, this becomes: \[ \rho (\vec{V} \cdot \nabla) \vec{V} = -\nabla p \]

Step 2: Compute Acceleration Terms

Given \(\vec{V} = u\hat{i} + v\hat{j} = (y^2 – x^2)\hat{i} + (2xy)\hat{j}\):

\[ (\vec{V} \cdot \nabla) \vec{V} = u\frac{\partial \vec{V}}{\partial x} + v\frac{\partial \vec{V}}{\partial y} \] Compute partial derivatives:

\[ \frac{\partial \vec{V}}{\partial x} = -2x\hat{i} + 2y\hat{j} \] \[ \frac{\partial \vec{V}}{\partial y} = 2y\hat{i} + 2x\hat{j} \] Now calculate the convective acceleration: \[ (\vec{V} \cdot \nabla) \vec{V} = (y^2 – x^2)(-2x\hat{i} + 2y\hat{j}) \]\[ + (2xy)(2y\hat{i} + 2x\hat{j}) \]

Step 3: Evaluate at (1,1)

At point (1,1): \[ u = 1^2 – 1^2 = 0, \quad v = 2×1×1 = 2 \] \[ \frac{\partial \vec{V}}{\partial x} = -2\hat{i} + 2\hat{j}, \quad \frac{\partial \vec{V}}{\partial y} = 2\hat{i} + 2\hat{j} \] \[ (\vec{V} \cdot \nabla) \vec{V} = 0 + 2(2\hat{i} + 2\hat{j}) = 4\hat{i} + 4\hat{j} \]

Step 4: Calculate Pressure Gradient

From Euler’s equation: \[ \nabla p = -\rho (\vec{V} \cdot \nabla) \vec{V} = -1.5 (4\hat{i} + 4\hat{j}) \]\[ = -6\hat{i} – 6\hat{j} \]

Step 5: Verify Irrotationality

Check if the flow is irrotational (though not necessary for solution):

\[ \omega = \frac{\partial v}{\partial x} – \frac{\partial u}{\partial y} = 2y – (-2y) = 4y \neq 0 \] The flow is rotational at y≠0, so we cannot use Bernoulli’s equation.

Final Answer: \(\boxed{C}\)

(A) \(\frac{1}{24}\) m/s

(B) \(\frac{1}{6}\) m/s

(C) \(\frac{1}{18}\) m/s

(D) \(\frac{1}{12}\) m/s

Solution =

⦾ Given:

✓ Bead diameter (d) = 0.1 mm = 0.0001 m

✓ Lead density (ρlead) = 11000 kg/m³

✓ Liquid viscosity (μ) = 1.1 × 10⁻³ kg/m·s

✓ Drag coefficient CD = 24/Re

✓ Gravity (g) = 10 m/s²

⦾ Solution Steps:

1. Calculate bead weight:

\[ W = \rho_{lead} \cdot \frac{\pi d^3}{6} \cdot g \] \[ W = 11000 \cdot \frac{\pi (0.0001)^3}{6} \cdot 10 \] \[ W \approx 5.76 \times 10^{-8} \, \text{N} \]

2. Drag force expression:

Given formula: \[ D = C_D \cdot \frac{1}{2}\rho V^2 \cdot \frac{\pi d^2}{4} \] With CD = 24/Re and Re = ρVd/μ: \[ D = \frac{24\mu}{\rho V d} \cdot \frac{1}{2}\rho V^2 \cdot \frac{\pi d^2}{4} \] Simplifies to: \[ D = 3\pi \mu V d \]

3. Force balance at terminal velocity:

\[ W = D \] \[ 5.76 \times 10^{-8} = 3\pi (1.1 \times 10^{-3}) V (0.0001) \] \[ V = \frac{5.76 \times 10^{-8}}{3\pi \times 1.1 \times 10^{-7}} \] \[ V \approx \frac{1}{18} \, \text{m/s} \]

⦾ Final Answer: \(\boxed{C}\) \(\frac{1}{18}\) m/s

(A) centre of buoyancy must coincide with the centre of gravity

(B) centre of buoyancy must be above the centre of gravity

(C) centre of gravity must be above the centre of buoyancy

(D) metacenter must be above the centre of gravity

Solution =

For a floating body to be stable, the metacenter (\( M \)) must lie above the center of gravity (\( G \)). This ensures a righting moment when the body tilts, restoring equilibrium.

⦾ Key Definitions:

✓ Center of Buoyancy (\( B \)): The centroid of the displaced fluid volume.

✓ Center of Gravity (\( G \)): The point where the body’s weight acts.

✓ Metacenter (\( M \)): The intersection point of the buoyancy line (after tilt) and the original vertical axis.

⦾ Stability Condition:

\[ \text{If } M \text{ is above } G \]\[ \Rightarrow \text{Stable} \\ \text{If } M \text{ coincides with } G \]\[ \Rightarrow \text{Neutral} \\ \text{If } M \text{ is below } G \Rightarrow \text{Unstable} \]

⦾ Why Other Options Are Incorrect:

✓ A) \( B \) need not coincide with \( G \) (neutral stability).

✓ B) \( B \) is usually below \( G \) in stable bodies (e.g., ships).

✓ C) \( G \) can be above \( B \) and still stable if \( M \) is above \( G \).

(A) \( \left( \frac{d_2}{d_1} \right)^{5 – n} \)

(B) \( \left( \frac{d_2}{d_1} \right)^5 \)

(C) \( \left( \frac{d_2}{d_1} \right)^{3 – n} \)

(D) \( \left( \frac{d_2}{d_1} \right)^{5 + n} \)

Solution =

We are given two pipes in series with diameters \( d_1 \) and \( d_2 \), equal lengths, and turbulent flow with friction factor \( f = k(Re)^{-n} \), where \( Re \) is the Reynolds number.

⦾ Step 1: Express the pressure drop

The frictional pressure drop in a pipe (Darcy-Weisbach equation) is: \[ \Delta P = f \frac{L}{d} \frac{\rho V^2}{2} \] where:

✓ \( f \) = friction factor

✓ \( L \) = pipe length

✓ \( d \) = pipe diameter

✓ \( \rho \) = fluid density

✓ \( V \) = flow velocity

⦾ Step 2: Relate velocities through continuity

For incompressible flow in series, the volumetric flow rate \( Q \) is constant: \[ Q = V_1 A_1 = V_2 A_2 \]\[ \implies V_1 = V_2 \left(\frac{d_2}{d_1}\right)^2 \]

⦾ Step 3: Express Reynolds number

Reynolds number is: \[ Re = \frac{\rho V d}{\mu} \implies Re \propto V d \] Thus: \[ \frac{Re_1}{Re_2} = \frac{V_1 d_1}{V_2 d_2} = \left(\frac{d_2}{d_1}\right)^2 \cdot \frac{d_1}{d_2} = \frac{d_2}{d_1} \]

⦾ Step 4: Express friction factors

Given \( f = k(Re)^{-n} \), the ratio is: \[ \frac{f_1}{f_2} = \left(\frac{Re_1}{Re_2}\right)^{-n} = \left(\frac{d_2}{d_1}\right)^{-n} \]

⦾ Step 5: Compute pressure drop ratio

Pressure drop ratio: \[ \frac{\Delta P_1}{\Delta P_2} = \frac{f_1 \frac{L}{d_1} \rho V_1^2}{f_2 \frac{L}{d_2} \rho V_2^2} = \frac{f_1}{f_2} \cdot \frac{d_2}{d_1} \cdot \left(\frac{V_1}{V_2}\right)^2 \] Substitute from previous steps: \[ = \left(\frac{d_2}{d_1}\right)^{-n} \cdot \frac{d_2}{d_1} \cdot \left(\frac{d_2}{d_1}\right)^4 = \left(\frac{d_2}{d_1}\right)^{5 – n} \]

⦾ Conclusion:

The correct answer is: \[ \boxed{A\ \left(\frac{d_2}{d_1}\right)^{(5-n)}} \]

(A) \( \frac{2}{\pi} \)

(B) \( 1 – \frac{2}{\pi} \)

(C) \( 1 + \frac{2}{\pi} \)

(D) \( 0 \)

Solution =

Given the velocity profile for boundary layer flow over a flat plate: \[ \frac{u}{U_\infty} = \sin\left(\frac{\pi}{2}\frac{y}{\delta}\right) \] where:

✓ \( U_\infty \) = free stream velocity

✓ \( \delta \) = local boundary layer thickness

✓ \( \delta^* \) = displacement thickness to be found

⦾ Step 1: Recall displacement thickness definition

Displacement thickness is defined as: \[ \delta^* = \int_0^\delta \left(1 – \frac{u}{U_\infty}\right) dy \]

⦾ Step 2: Substitute the given velocity profile

Using the given profile: \[ \delta^* = \int_0^\delta \left(1 – \sin\left(\frac{\pi}{2}\frac{y}{\delta}\right)\right) dy \]

⦾ Step 3: Solve the integral

Let \( \eta = \frac{y}{\delta} \), then \( dy = \delta d\eta \), and limits change from 0 to 1: \[ \delta^* = \delta \int_0^1 \left(1 – \sin\left(\frac{\pi}{2}\eta\right)\right) d\eta \] \[ = \delta \left[ \int_0^1 1 \, d\eta – \int_0^1 \sin\left(\frac{\pi}{2}\eta\right) d\eta \right] \] \[ = \delta \left[ 1 – \left( -\frac{2}{\pi} \cos\left(\frac{\pi}{2}\eta\right) \bigg|_0^1 \right) \right] \] \[ = \delta \left[ 1 – \left( -\frac{2}{\pi} (0 – 1) \right) \right] \] \[ = \delta \left[ 1 – \frac{2}{\pi} \right] \]

⦾ Step 4: Compute the ratio

The required ratio is: \[ \frac{\delta^*}{\delta} = 1 – \frac{2}{\pi} \]

⦾ Conclusion: The correct answer is: \[ \boxed{B\ 1 – \frac{2}{\pi}} \]

(A) flow from S1 to S2 and head loss is 0.53m

(B) flow from S2 to S1 and head loss is 0.53m

(C) flow from S1 to S2 and head loss is 1.06m

(D) flow from S2 to S1 and head loss is 1.06m

Solution =

To solve this, we apply the Bernoulli equation including head loss between two sections \( S_1 \) and \( S_2 \):

\[ \frac{P_1}{\gamma} + \frac{V_1^2}{2g} + z_1 = \frac{P_2}{\gamma} + \frac{V_2^2}{2g} + z_2 + h_f \]

⦾ Where:

✓ \( P_1 = 50\,\text{kPa} = 50000\,\text{Pa} \)

✓ \( z_1 = 10\,\text{m} \)

✓ \( V_1 = V_2 = 2\,\text{m/s} \) (same diameter, so same velocity)

✓ \( P_2 = 20\,\text{kPa} = 20000\,\text{Pa} \)

✓ \( z_2 = 12\,\text{m} \)

✓ \( \gamma = \rho g = 1000 \times 9.8 = 9800\,\text{N/m}^3 \)

⦾ Step-by-step:

✓ Left side (S1):

\[ \frac{P_1}{\gamma} + \frac{V^2}{2g} + z_1 \]\[ = \frac{50000}{9800} + \frac{2^2}{2 \times 9.8} + 10 \]\[ = 5.102 + 0.204 + 10 = 15.306\,\text{m} \]

✓ Right side (S2):

\[ \frac{P_2}{\gamma} + \frac{V^2}{2g} + z_2 \]\[ = \frac{20000}{9800} + 0.204 + 12 \]\[ = 2.041 + 0.204 + 12 = 14.245\,\text{m} \]

✓ Head loss:

\[ h_f = 15.306 – 14.245 = \boxed{1.06\,\text{m}} \]

✓ Flow direction:

Since total head at \( S_1 > S_2 \), the flow is from \( S_1 \) to \( S_2 \).

⦾ Final Answer:

C. flow from S1 to S2 and head loss is 1.06 m

(A) steady flow

(B) irrotational flow

(C) inviscid flow

(D) incompressible flow

Solution =

⦾ Correct Answer: D) Incompressible flow

⦾ Explanation:

✓ Steady flow (Option A): No change with respect to time, but density may vary — not sufficient.

✓ Irrotational flow (Option B): Implies zero vorticity (\( \nabla \times \vec{V} = 0 \)), not related to mass conservation.

✓ Inviscid flow (Option C): Neglects viscosity, but doesn’t imply anything about compressibility or continuity.

✓ Incompressible flow (Option D): Implies constant density, and the continuity equation becomes: \[ \nabla \cdot \vec{V} = 0 \] which is the condition given in the question.

Thus, the correct and necessary condition for the given continuity equation is incompressible flow.

(A) \( u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} \)

(B) \( u \frac{\partial u}{\partial x} + v \frac{\partial v}{\partial y} \)

(C) \( u \frac{\partial v}{\partial x} + v \frac{\partial u}{\partial y} \)

(D) \( v \frac{\partial u}{\partial x} + u \frac{\partial u}{\partial y} \)

Solution =

In a two-dimensional velocity field with velocity components \( u \) along the \( x \)-direction and \( v \) along the \( y \)-direction, the convective acceleration along the x-direction is given by:

\[ a_x = u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} \]

This represents the change in the x-component of velocity due to spatial variations in both \( x \) and \( y \) directions.

⦾ Correct Option: A

\[ \boxed{u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y}} \]

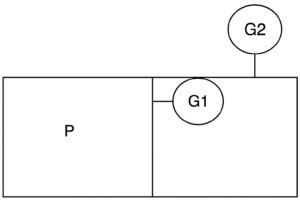

(A) 1.01 bar

(B) 2.01 bar

(C) 5.00 bar

(D) 7.01 bar

Solution =

⦾ Given:

✓ \( P_{G_1} = 5 \, \text{bar} \)

✓ \( P_{G_2} = 1 \, \text{bar} \)

✓ \( P_{\text{atm}} = 1.01 \, \text{bar} \)

⦾ Step 1: For pressure gauge \( G_2 \)

Absolute pressure at \( G_2 \) is calculated as: \[ P_{\text{abs}, G_2} = P_{\text{atm}} + P_{G_2} \]\[ = 1.01 + 1 = 2.01 \, \text{bar} \]

Since this is connected to atmospheric reference, we assume: \[ P_{\text{local atm (for G}_1)} = 2.01 \, \text{bar} \]

⦾ Step 2: For pressure gauge \( G_1 \)

Absolute pressure at \( G_1 \) (i.e., pressure \( P \)) is: \[ P = P_{\text{local atm}} + P_{G_1} \]\[ = 2.01 + 5 = 7.01 \, \text{bar} \]

⦾ Final Answer: \( \boxed{7.01 \, \text{bar}} \)

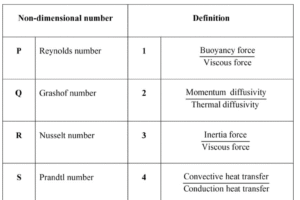

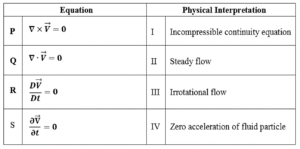

(A) P-1, Q-3, R-2, S-4

(B) P-3, Q-1, R-2, S-4

(C) P-4, Q-3, R-1, S-2

(D) P-3, Q-1, R-4, S-2

Solution =

(Matching the Non-Dimensional Numbers):

(Symbol => Non-dimensional Number => Matching Definition)

✓ P => Reynolds number => 3

✓ Q => Grashof number => 1

✓ R => Nusselt number => 4

✓ S => Prandtl number => 2

So, the correct matching is:

P → 3

Q → 1

R → 4

S → 2

⦾ Final Answer: Option D

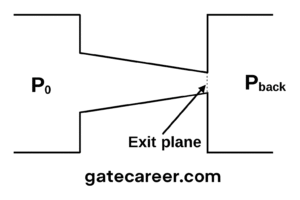

(A) Mass flow rate through the nozzle will remain unchanged.

(B) Mach number at the exit plane of the nozzle will remain unchanged at unity.

(C) Mass flow rate through the nozzle will increase.

(D) Mach number at the exit plane of the nozzle will become more than unity.

Solution =

⦾ Key Concepts:

✓ A convergent nozzle reaches choked flow when the flow at the exit plane reaches Mach number = 1.

✓ Once choked, increasing the upstream total pressure \( P_0 \) while keeping the back pressure \( P_{\text{back}} \) constant does not change the Mach number at the exit; it remains unity.

✓ Mass flow rate through a choked nozzle increases with increase in \( P_0 \), because the mass flow rate under choked conditions is given by:

\[ \dot{m} = C A^\ast P_0 \sqrt{\frac{\gamma}{R T_0}} \left( \frac{2}{\gamma + 1} \right)^{\frac{\gamma + 1}{2(\gamma – 1)}} \]

where \( C \) is a constant, \( A^\ast \) is the throat area. This shows that \( \dot{m} \propto P_0 \), if \( T_0 \) is constant.

⦾ Now consider the options:

A. Mass flow rate through the nozzle will remain unchanged.

→ False, because \( \dot{m} \) increases with \( P_0 \).

B. Mach number at the exit plane of the nozzle will remain unchanged at unity.

→ True, because choked flow ensures \( M = 1 \) at the exit of a convergent nozzle.

C. Mass flow rate through the nozzle will increase.

→ True, from the mass flow rate equation under choked conditions.

D. Mach number at the exit plane of the nozzle will become more than unity.

→ False, since this is not possible in a purely convergent nozzle.

⦾ Correct Answers: B and C

(A) Ratio of inertial force to viscous force.

(B) Ratio of buoyancy force to viscous force.

(C) Viscous force per unit mass.

(D) Buoyancy force per unit mass.

Solution =

In the 2D momentum equation for natural convection:

\[ u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} = g \beta (T – T_\infty) + \nu \frac{\partial^2 u}{\partial y^2} \]

The term \( g \beta (T – T_\infty) \) represents the buoyancy force per unit mass, which drives natural convection due to density differences caused by temperature gradients.

⦾ Correct Answer: D

(A) \( x^2 y^2 = \text{constant} \)

(B) \( x y^2 = \text{constant} \)

(C) \( 2xy – y^2 = \text{constant} \)

(D) \( xy = \text{constant} \)

Solution =

Given the two-dimensional incompressible flow velocity field: \[ \vec{u} = 2xy\hat{i} – y^2\hat{j} \] We need to find the equation for its streamlines.

⦾ Step 1: Recall streamline equation

For 2D flow, streamlines satisfy: \[ \frac{dy}{dx} = \frac{v}{u} = \frac{-y^2}{2xy} = \frac{-y}{2x} \]

⦾ Step 2: Solve the differential equation

Separate variables: \[ \frac{dy}{y} = \frac{-dx}{2x} \] Integrate both sides: \[ \ln|y| = -\frac{1}{2}\ln|x| + C \] Exponentiate: \[ y = e^C x^{-1/2} \implies y\sqrt{x} = \text{constant} \] Square both sides: \[ x y^2 = \text{constant} \]

⦾ Step 3: Verify with given options

The solution matches option B: \( xy^2 = \text{constant} \)

⦾ Conclusion:

The correct answer is: \[ \boxed{B\ xy^2 = \text{constant}} \]

(A) linear

(B) exponential

(C) quadratic

(D) cubic

Solution =

To determine how atmospheric pressure varies with height under constant temperature conditions for an ideal gas, we analyze the hydrostatic equilibrium and ideal gas law.

⦾ Step 1: Hydrostatic Equilibrium

The pressure variation with height is given by: \[ \frac{dP}{dz} = -\rho g \] where:

✓ \( P \) = pressure

✓ \( \rho \) = density

✓ \( g \) = acceleration due to gravity

✓ \( z \) = height

⦾ Step 2: Ideal Gas Law

For an ideal gas at constant temperature: \[ P = \rho R T \] where:

✓ \( R \) = specific gas constant

✓ \( T \) = temperature (constant)

Thus, density can be expressed as: \[ \rho = \frac{P}{RT} \]

⦾ Step 3: Differential Equation

Substitute the density into the hydrostatic equation: \[ \frac{dP}{dz} = -\left(\frac{P}{RT}\right) g \] Rearrange: \[ \frac{dP}{P} = -\frac{g}{RT} dz \]

⦾ Step 4: Solve the Differential Equation

Integrate both sides: \[ \int \frac{dP}{P} = -\frac{g}{RT} \int dz \] \[ \ln P = -\frac{g}{RT} z + C \] Exponentiate to solve for pressure: \[ P = P_0 e^{-\frac{g}{RT}z} \] where \( P_0 \) is the pressure at \( z = 0 \).

⦾ Step 5: Conclusion

The pressure varies exponentially with height under constant temperature conditions.

⦾ Final Answer:

The correct answer is: \[ \boxed{B\ \text{exponential}} \]

(A) |Ψ₁ + Ψ₂|

(B) Ψ₁Ψ₂

(C) Ψ₁/Ψ₂

(D) |Ψ₁ – Ψ₂|

Solution =

The volumetric flow rate (per unit depth) between two streamlines is determined by the difference in their stream function values.

⦾ Key Concept:

In fluid mechanics, the stream function (Ψ) has these properties:

✓ The flow rate between two streamlines is equal to the difference in their stream function values

✓ This relationship holds for both 2D incompressible flow and axisymmetric flow

✓ The direction of flow is from the higher Ψ value to the lower Ψ value

⦾ Mathematical Representation:

The volumetric flow rate per unit depth between two streamlines is: \[ Q = |Ψ_1 – Ψ_2| \] where:

✓ \( Ψ_1 \) = stream function value of first streamline

✓ \( Ψ_2 \) = stream function value of second streamline

⦾ Analysis of Options:

A. |Ψ₁ + Ψ₂| – Incorrect (sum is not physically meaningful here)

B. Ψ₁Ψ₂ – Incorrect (product of stream functions has no flow interpretation)

C. Ψ₁/Ψ₂ – Incorrect (ratio of stream functions is not relevant)

D. |Ψ₁ – Ψ₂| – Correct (matches the fundamental definition)

⦾ Conclusion:

The correct answer is: \[ \boxed{D\ |Ψ_1 – Ψ_2|} \]

(A) 177

(B) 354

(C) 500

(D) 707

Solution =

To solve this, we use the affinity laws for hydraulic turbines, specifically the relationship between power and head:

\[ P \propto H^{3/2} \]

⦾ Given:

✓ \( P_1 = 1000 \, \text{kW} \)

✓ \( H_1 = 40 \, \text{m} \)

✓ \( H_2 = 20 \, \text{m} \)

⦾ Using the relationship:

\[ \frac{P_2}{P_1} = \left( \frac{H_2}{H_1} \right)^{3/2} = \left( \frac{20}{40} \right)^{3/2} \]\[= \left( \frac{1}{2} \right)^{3/2} = \frac{1}{2^{3/2}} = \frac{1}{\sqrt{8}} \approx 0.3536 \]

So the power developed at 20 m head is:

\[ P_2 = P_1 \times 0.3536 = 1000 \times 0.3536 \]\[\approx 354 \, \text{kW} \]

⦾ Final Answer: \(\boxed{\text{B. 354}}\)

P. A gas cools upon expansion only when its Joule-Thomson co-efficient is positive in the temperature range of expansion.

Q. For a system undergoing a process, its entropy remains constant only when the process is reversible.

R. The work done by a closed system in an adiabatic process is a point function.

S. A liquid expands upon freezing when the slope of its fusion curve on Pressure-Temperature diagram is negative.

(A) R and S

(B) P and Q

(C) Q, R and S

(D) P, Q and R

Solution =

⦾ Statement P:

A gas cools upon expansion only when its Joule-Thomson coefficient is positive in the temperature range of expansion.

✓ The Joule-Thomson coefficient (\( \mu_{JT} \)) determines whether a gas cools or heats upon expansion (throttling process).

✓ If \( \mu_{JT} > 0 \), the gas cools upon expansion.

✓ If \( \mu_{JT} < 0 \), the gas heats upon expansion.

Correctness: True because cooling occurs only when \( \mu_{JT} > 0 \).

⦾ Statement Q:

For a system undergoing a process, its entropy remains constant only when the process is reversible.

✓ Entropy (\( S \)) remains constant (\( \Delta S = 0 \)) for reversible adiabatic processes.

✓ However, entropy can also remain constant in other isentropic processes (not necessarily reversible if there is compensating irreversibility).

Correctness: False because entropy can remain constant even in some irreversible processes.

⦾ Statement R:

The work done by a closed system in an adiabatic process is a point function.

✓ In an adiabatic process, no heat is transferred (\( Q = 0 \)). From the First Law: \[ \Delta U = -W \]

✓ Since \( \Delta U \) (change in internal energy) is a point function (depends only on initial and final states), \( W \) is also a point function.

Correctness: True.

⦾ Statement S:

A liquid expands upon freezing when the slope of its fusion curve on the Pressure-Temperature diagram is negative.

✓ The fusion curve (solid-liquid equilibrium) on a \( P-T \) diagram has a slope given by the Clausius-Clapeyron equation: \[ \frac{dP}{dT} = \frac{\Delta S}{\Delta V} \]

✓ If the slope is negative, \( \Delta V \) (volume change upon freezing) must be negative (i.e., the liquid expands upon freezing, as in water).

Correctness: True.

⦾ Combination Analysis:

P: True

Q: False

R: True

S: True

The correct combination is R and S (Option A).

⦾ Note: Option C (Q, R, and S) is incorrect because Q is false. Option D (P, Q, and R) is incorrect because Q is false. Option B (P and Q) is incorrect because Q is false.

(A) 48 m

(B) 64 m

(C) 120 m

(D) 142 m

Solution =

A leaf is caught in a whirlpool. At a given instant, the leaf is at a distance of 120 m from the center of the whirlpool. The velocity distribution is given by:

\( V_r = -\left( \frac{60 \times 10^3}{2\pi r} \right) \, \text{m/s}, \)\( V_\theta = \frac{300 \times 10^3}{2\pi r} \, \text{m/s} \)

We are to find the distance from the center after the leaf has moved through half a revolution, i.e., \( \theta = \pi \) radians.

⦾ Step-by-step Solution:

Angular velocity: \[ \frac{d\theta}{dt} = \frac{V_\theta}{r} = \frac{300 \times 10^3}{2\pi r^2} \]

Radial velocity: \[ \frac{dr}{dt} = V_r = -\frac{60 \times 10^3}{2\pi r} \]

Divide both expressions to eliminate time \( t \): \[ \frac{dr}{d\theta} = \frac{\frac{dr}{dt}}{\frac{d\theta}{dt}} = \frac{-\frac{60 \times 10^3}{2\pi r}}{\frac{300 \times 10^3}{2\pi r^2}} \]\[ = -\frac{60 \times 10^3}{300 \times 10^3} \cdot r = -\frac{1}{5}r \]

This is a separable differential equation: \[ \frac{dr}{r} = -\frac{1}{5} d\theta \]

Integrate both sides: \[ \int_{r_0}^{r} \frac{1}{r} dr = -\frac{1}{5} \int_0^{\pi} d\theta \] \[ \ln r – \ln r_0 = -\frac{\pi}{5} \Rightarrow \ln\left(\frac{r}{r_0}\right) \] \[= -\frac{\pi}{5} \Rightarrow \frac{r}{r_0} = e^{-\pi/5} \Rightarrow r = r_0 \cdot e^{-\pi/5} \]

Given \( r_0 = 120 \, \text{m} \), we get: \[ r = 120 \cdot e^{-\pi/5} \approx 120 \cdot e^{-0.6283} \]\[\approx 120 \cdot 0.533 \approx 63.96 \, \text{m} \]

⦾ Final Answer:

\[ \boxed{64 \, \text{m}} \quad \text{(Option B)} \]

(A) 0.449 bar

(B) 5.503 bar

(C) 44.911 bar

(D) 55.203 bar

Solution =

⦾ Given:

✓ Distance from pump to tank: \( L = 4\, \text{km} = 4000\, \text{m} \)

✓ Pipe diameter: \( D = 0.2\, \text{m} \)

✓ Darcy’s friction factor: \( f = 0.01 \)

✓ Water velocity in pipe: \( v = 2\, \text{m/s} \)

✓ Head to be maintained in tank: \( H_{\text{tank}} = 5\, \text{m} \)

✓ Atmospheric pressure: \( P_{\text{atm}} = 1.01\, \text{bar} \)

✓ Minor losses: Neglected

⦾ Step 1: Friction head loss (Darcy-Weisbach equation)

\[ h_f = f \cdot \frac{L}{D} \cdot \frac{v^2}{2g} \] Substituting the values: \[ h_f = 0.01 \cdot \frac{4000}{0.2} \cdot \frac{2^2}{2 \cdot 9.81} \] \[ h_f = 0.01 \cdot 20000 \cdot \frac{4}{19.62} \] \[= 200 \cdot 0.2039 = 40.78\, \text{m} \]

⦾ Step 2: Total head required at pump discharge

\[ H_{\text{pump}} = h_f + H_{\text{tank}} \] \[= 40.78 + 5 = 45.78\, \text{m} \]

⦾ Step 3: Convert head to pressure

\[ P = \rho g H \] where \( \rho = 1000\, \text{kg/m}^3 \), \( g = 9.81\, \text{m/s}^2 \) \[ P = 1000 \cdot 9.81 \cdot 45.78 = 449114.1\, \text{Pa} \] Converting to bar: \[ P = \frac{449114.1}{100000} \] \[= \boxed{4.491\, \text{bar (gauge pressure)}} \]

⦾ Step 4: Add atmospheric pressure for absolute pressure

\[ P_{\text{abs}} = 4.491 + 1.01 = \boxed{5.501\, \text{bar}} \]

⦾ Final Answer: Option B: 5.503 bar

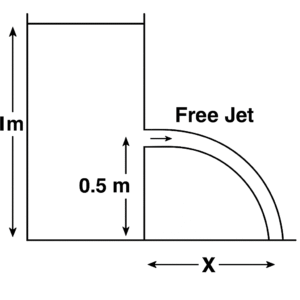

(A) 0.5

(B) 1

(C) 2

(D) 4

Solution =

⦾ Given:

✓ Height of water level from hole: \( h = 0.5 \, \text{m} \)

✓ Height of hole from ground: \( s = 0.5 \, \text{m} \)

⦾ Step 1: Velocity of water jet from the hole (Torricelli’s theorem)

\[ v = \sqrt{2gh} \]

⦾ Step 2: Time taken to fall a vertical distance \( s \)

Using second equation of motion for free fall:

\[ t = \sqrt{\frac{2s}{g}} \]

⦾ Step 3: Horizontal distance traveled

\[ X = v \cdot t = \sqrt{2gh} \cdot \sqrt{\frac{2s}{g}} = \sqrt{4hs} \]

Substitute \( h = 0.5 \, \text{m}, s = 0.5 \, \text{m} \):

\[ X = \sqrt{4 \cdot 0.5 \cdot 0.5} = \sqrt{1} = 1 \, \text{m} \]

⦾ Final Answer:

\[ \boxed{1 \, \text{m}} \quad \text{(Option B)} \]

(A) \( x^2 y = 1 \)

(B) \( x y^2 = 1 \)

(C) \( x^2 y^2 = 1 \)

(D) \( \frac{x}{y^2} = 1 \)

Solution =

A two-dimensional flow has velocities in x and y directions given by \( u = 2xyt \) and \( v = -y^2 t \), where \( t \) denotes time. The equation for the streamline passing through \( x = 1, y = 1 \) is:

⦾ Streamline Equation:

The differential equation for streamlines is: \[ \frac{dy}{dx} = \frac{v}{u} \]

Substitute the given values of \( u \) and \( v \): \[ \frac{dy}{dx} = \frac{-y^2 t}{2xyt} = \frac{-y}{2x} \] The time \( t \) cancels out, so the streamline shape is time-independent (though the pathline would be time-dependent).

Now solve: \[ \frac{dy}{dx} = \frac{-y}{2x} \Rightarrow \frac{dy}{y} = \frac{-dx}{2x} \]

Integrate both sides: \[ \int \frac{1}{y} \, dy = -\frac{1}{2} \int \frac{1}{x} \, dx \Rightarrow \ln y \] \[= -\frac{1}{2} \ln x + C \] \[ \ln y + \frac{1}{2} \ln x = C \Rightarrow \ln(y x^{1/2}) = C \] \[\Rightarrow y x^{1/2} = C_1 \Rightarrow x^{1/2} y = C_1 \] \[\Rightarrow \boxed{x y^2 = \text{constant}} \]

Apply the condition \( x = 1, y = 1 \): \[ 1 \cdot 1^2 = 1 \Rightarrow \text{constant} = 1 \]

⦾ Final Streamline Equation:

\[ \boxed{x y^2 = 1} \]

⦾ Correct Answer: Option B

(A) \( u \frac{\partial u}{\partial x} + u \frac{\partial v}{\partial y} \)

(B) \( 2u \frac{\partial u}{\partial x} + u \frac{\partial v}{\partial y} \)

(C) \( 2u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} + u \frac{\partial v}{\partial y} \)

(D) \( v \frac{\partial u}{\partial x} + v \frac{\partial v}{\partial y} \)

Solution =

⦾ Step-by-step Simplification: We are given the expression for a two-dimensional incompressible flow with velocity components \( u \) and \( v \) in the \( x \) and \( y \) directions respectively:

\[ \frac{\partial (u^2)}{\partial x} + \frac{\partial (uv)}{\partial y} \]

We aim to simplify this expression.

⦾ Step 1: Apply the product rule

\[ \frac{\partial (u^2)}{\partial x} = 2u \frac{\partial u}{\partial x} \]

\[ \frac{\partial (uv)}{\partial y} = u \frac{\partial v}{\partial y} + v \frac{\partial u}{\partial y} \]

⦾ Step 2: Combine the terms

\[ \frac{\partial (u^2)}{\partial x} + \frac{\partial (uv)}{\partial y} \] \[= 2u \frac{\partial u}{\partial x} + u \frac{\partial v}{\partial y} + v \frac{\partial u}{\partial y} \]

⦾ Step 3: Group the terms neatly

\[ = 2u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} + u \frac{\partial v}{\partial y} \]

⦾ Final Answer: Option C

\[ \boxed{ 2u \frac{\partial u}{\partial x} + v \frac{\partial u}{\partial y} + u \frac{\partial v}{\partial y} } \]

(A) centroid of the floating body

(B) center of gravity of the body

(C) centroid of the fluid vertically below the body

(D) centroid of the displaced fluid

Solution =

For a floating body, the buoyant force and its point of application are determined by Archimedes’ principle:

⦾ Key Concept:

The buoyant force:

✓ Equals the weight of the displaced fluid

✓ Acts vertically upward

Passes through the centroid of the displaced fluid volume (called the center of buoyancy)

⦾ Analysis of Options:

A. centroid of the floating body – Incorrect (not relevant for buoyancy)

B. center of gravity of the body – Incorrect (this is where weight acts)

C. centroid of the fluid vertically below the body – Incorrect (misinterpretation)

D. centroid of the displaced fluid – Correct (this is the center of buoyancy)

⦾ Visualization:

The buoyant force acts through the center of buoyancy (B), while the weight acts through the center of gravity (G). The relative positions of B and G determine stability.

⦾ Conclusion:

The correct answer is: \[ \boxed{D\ \text{centroid of the displaced fluid}} \]

(A) \( \frac{u’}{2} \)

(B) \( -\frac{\bar{u}}{2} \)

(C) zero

(D) \( \frac{\bar{u}}{2} \)

Solution =

Given the instantaneous stream-wise velocity in turbulent flow: \[ u(x, y, z, t) = \tilde{u}(x, y, z) + u'(x, y, z, t) \] where:

✓ \(\tilde{u}\) = time-averaged velocity component

✓ \(u’\) = fluctuating velocity component

⦾ Key Concept:

In Reynolds decomposition for turbulent flow:

The time-average of the steady component \(\tilde{u}\) is \(\tilde{u}\) itself

The time-average of the fluctuating component \(u’\) is zero by definition

Mathematically: \[ \overline{u’} = \lim_{T\to\infty} \frac{1}{T} \int_0^T u’ \, dt = 0 \]

⦾ Analysis of Options:

A. \(u’/2\) – Incorrect (fluctuations average to zero, not half their value)

B. \(-\tilde{u}/2\) – Incorrect (no relation between mean and fluctuation averages)

C. zero – Correct (by definition of Reynolds decomposition)

D. \(\tilde{u}/2\) – Incorrect (mean component doesn’t affect fluctuation average)

⦾ Physical Interpretation:

The fluctuating component \(u’\) represents random deviations from the mean, which:

✓ Have positive and negative values with equal probability over time

✓ Cancel out when averaged over sufficiently long time periods

⦾ Conclusion:

The correct answer is: \[ \boxed{C\ \text{zero}} \]

(i) the local pressure is reduced to vapor pressure

(ii) cavitation starts

(iii) boiling of liquid starts

(iv) cavitation stops

(A) (i), (ii) and (iv)

(B) only (ii) and (iii)

(C) (i), (iii) and (iv)

(D) (i), (ii) and (iii)

Solution =

The cavitation parameter (also called Thoma cavitation number, denoted by \( \sigma \)) is given by:

\[ \sigma = \frac{P_{\text{atm}} – P_v}{\frac{1}{2} \rho V^2} \]

⦾ Where: